Plan manufacturing orders

We will help you plan your production orders taking into account the technology, time-consumption of the operation, performance of machines, production lines, employee shift calendar, availability of raw materials, retooling and many others. Phew, there are so many of them!

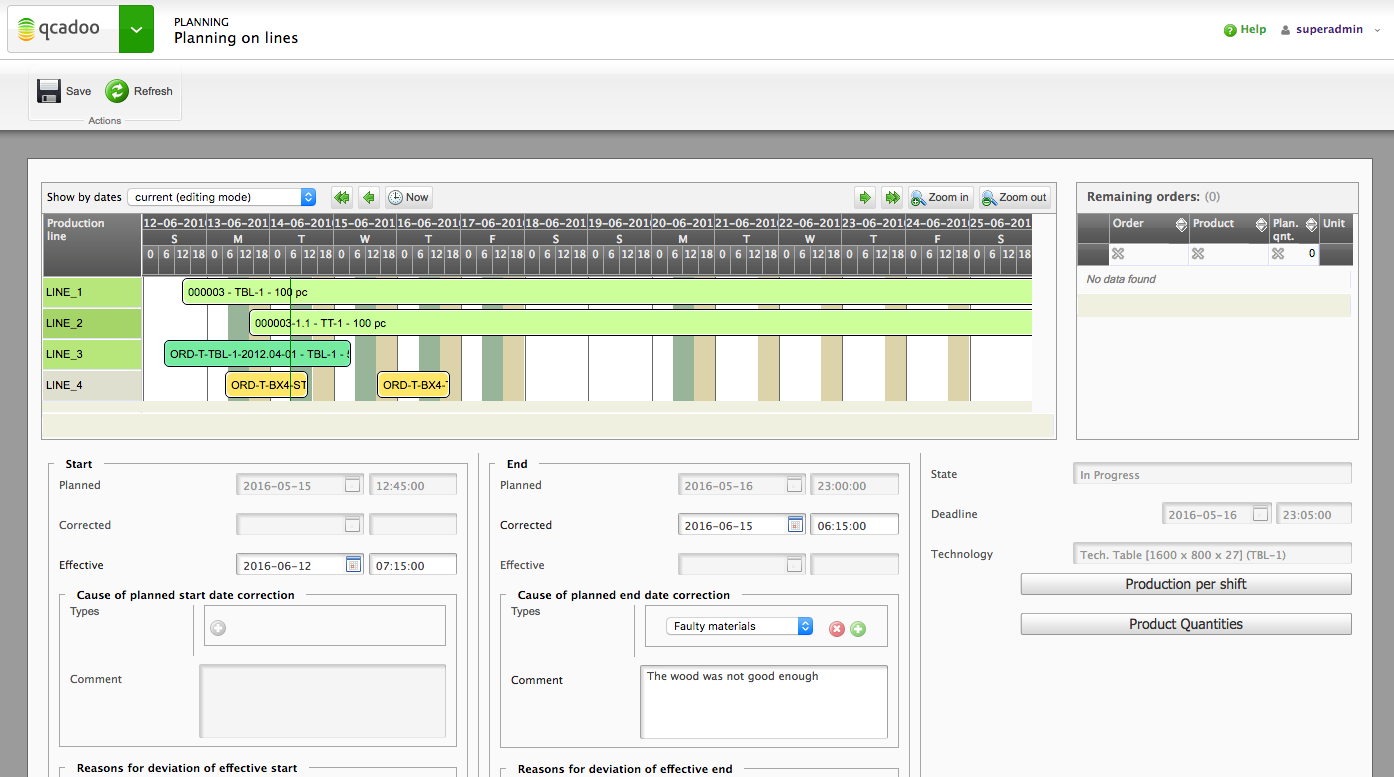

Graphical planning on production lines

qcadoo MES will allow you to easily arrange orders on particular production lines. Each order can be freely transferred using a mouse. You can see its details and plan particular shifts to execute the order. Additionally, the necessary retooling operations will be taken into account between particular orders. Everything is done so that work at your plant is fast and pleasant.

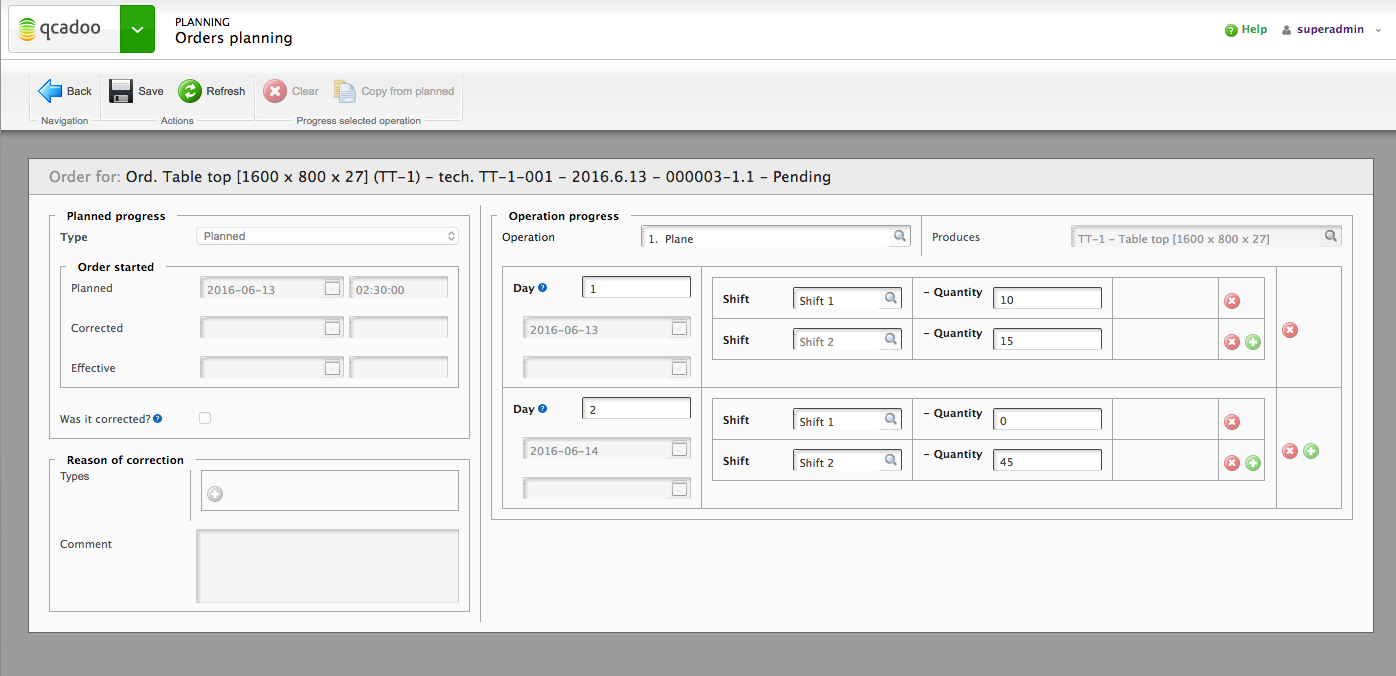

Production per shifts

When your orders last long, are executed for several days and take place throughout a few working shifts, it is not easy to plan work effectively limiting the number of stoppages to a minimum. qcadoo MES will help you plan an order taking into account the calendar of employee shifts, available resources, assumed capacity of machines and retooling operations. Everything is completed automatically.

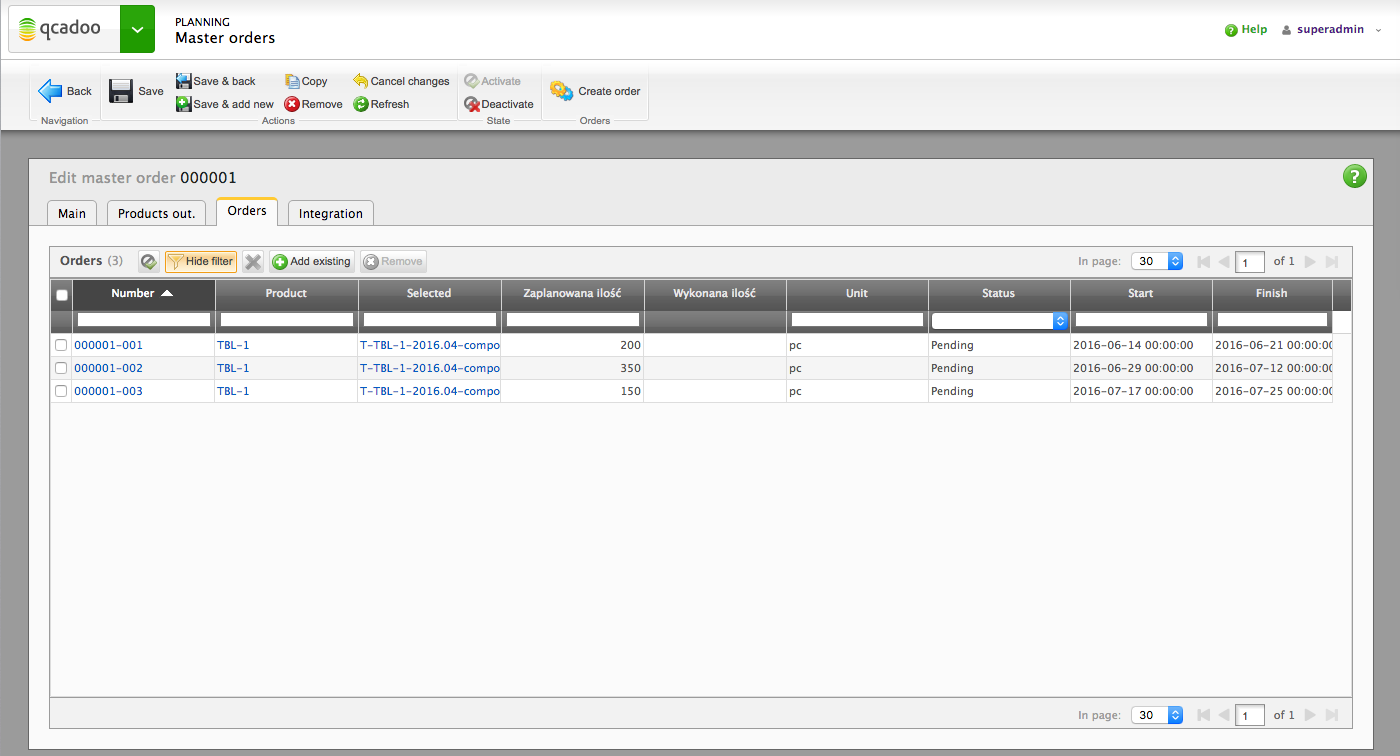

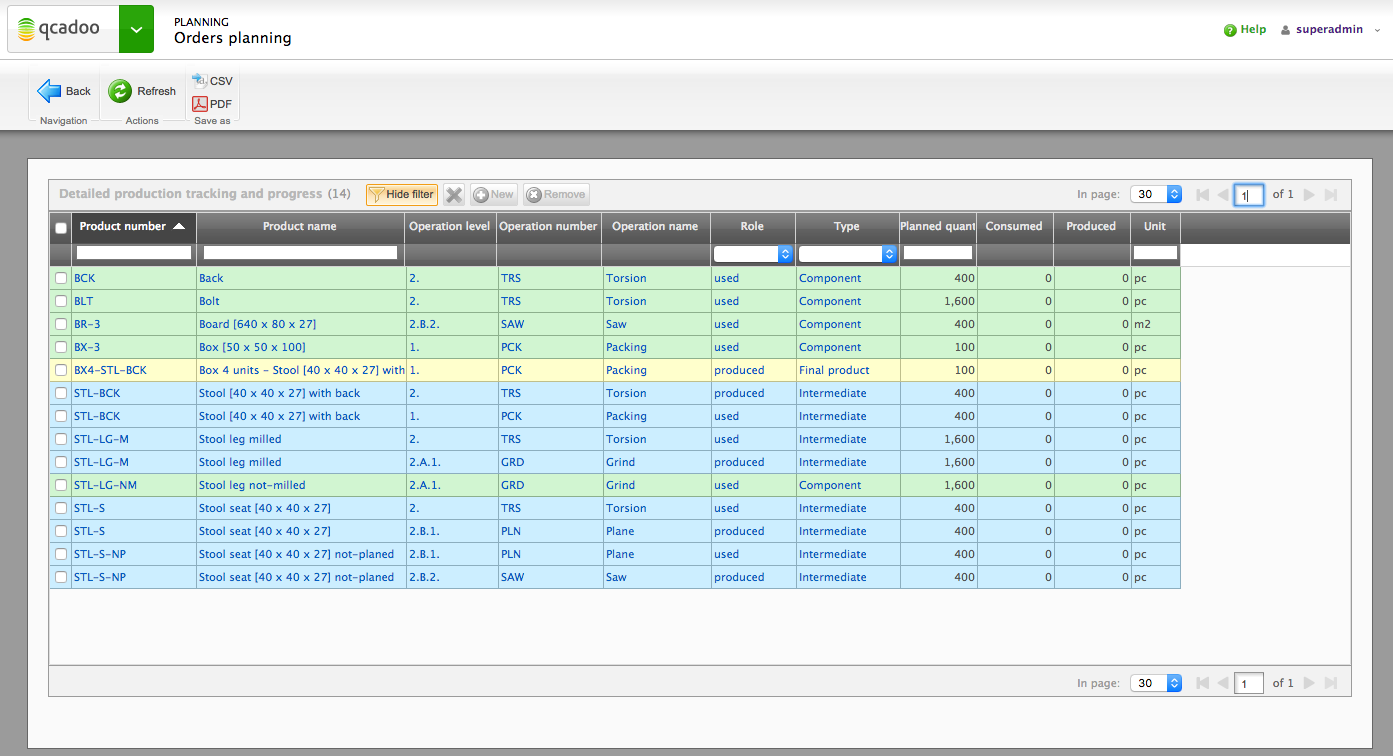

Batch planning for master orders

In some cases, your customers order large product volumes which are to be collected in batches produced, for instance, in monthly cycles. Effective planning or progress tracking can be a long and time-consuming process. Thanks to qcadoo MES’s Master Orders, you can easily plan a large order and separate it into smaller batches, completed in particular time cycles. You can also track their progress.

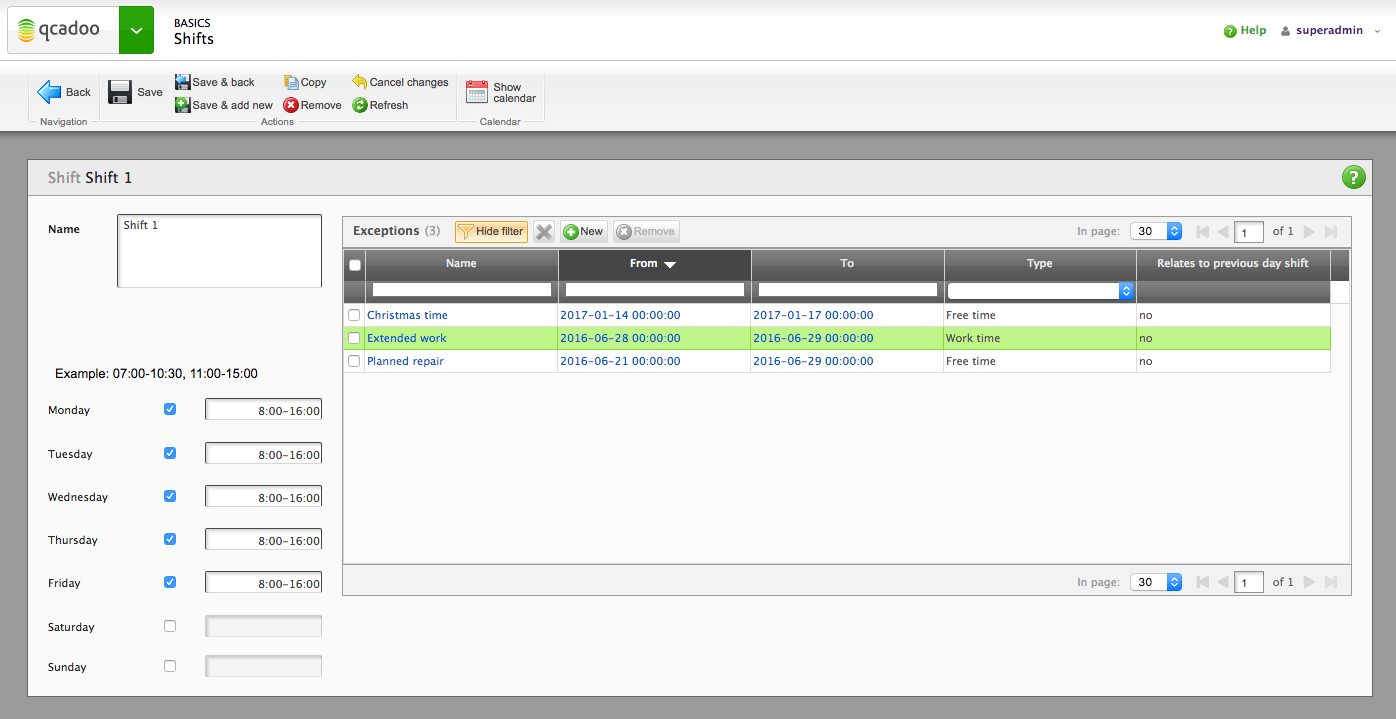

Shifts calendar

Using a built-in shift calendar, you can easily define shifts at your company. For each shift you can assign appropriate employees, and define all applicable exceptions (holidays, overtime). This is the basis which is used when calculating the time-consumption of orders and their planning.

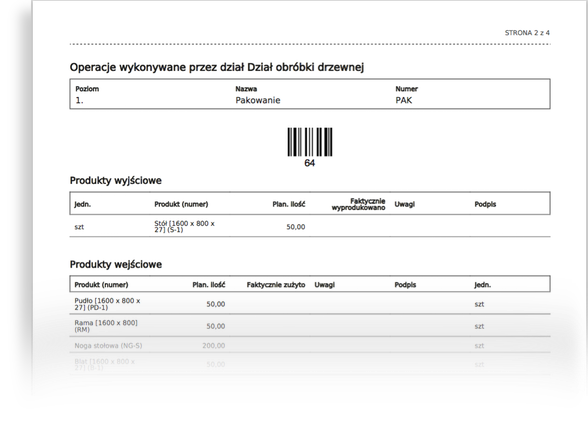

Generate work instructions

The work instructions are handed out to employees to provide them with information on what should be produced by them and which raw materials should be used in particular operations. You can print them for many orders simultaneously while grouping operations according to any method, e.g. per Departments, Machines or Work Stations. The work instruction can be printed with attachments necessary for proper completion of an order, such as drawings or specifications. Barcodes in each operation enable fast and effective registration of production.

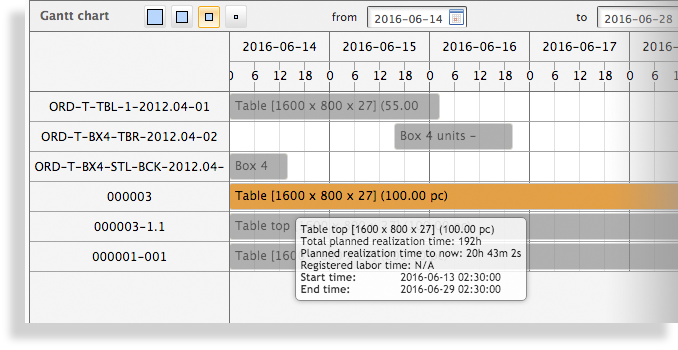

Graphical scheduler with progress indication

Orders are presented in a clear way using a Gantt chart. You can quickly see what is planned, what the progress is and whether there are any delays. By analyzing the planned production, your commercial department is able to specify reliable lead times to your customers.

Raw materials change during production

If in the process of the order you are short of a raw material, you can use a different one by modifying the material structure in the order. Applicable warehouse documents will be generated for such materials and their cost will increase the total cost of the order. The entire history of changes will be visible in the order so that you are aware of all stages.

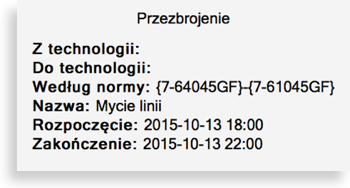

Consideration of changeovers

qcadoo MES enables to determine the time of retooling operations in the context of a given production line, and what’s worth noting, taking into account the subsequent orders. After all, cleaning a machine from black paint when you want to use it for white paint later, will take longer than cleaning it from yellow paint to prepare it for using orange paint. You can easily plan orders knowing that the system will take retooling operations into account when planning production.

Friendly manufacturing management

Qcadoo Limited Sp. z o.o.

ul. Walerego Sławka 3A

30-633 Kraków, Polska

+48 881 501 347

welcome(at)qcadoo.com